Heavy Metal removal

ADVANTAGES OVER SULPHIDE OR HYDROXIDE PRECIPITATION

applications

Plating industry

Metal finishing

Printed circuit board manufacture

Aerospace

Automotive

Battery manufacture

Incineration plant

Thermal power plant

Waste disposal contractors

Polluted groundwater

Washing contaminated land/soil

Iron and steel manufacture

Photographic industry

Printing industry

Chemical industry

Electronics industry

Metal finishing

Printed circuit board manufacture

Aerospace

Automotive

Battery manufacture

Incineration plant

Thermal power plant

Waste disposal contractors

Polluted groundwater

Washing contaminated land/soil

Iron and steel manufacture

Photographic industry

Printing industry

Chemical industry

Electronics industry

sulphates

Sulphates can only be precipitated at ambient temperature to between 1500-1800mg/l and in the presence of sodium and potassium ions this is higher and often the limit of solubility is around 2500mg/l.

Water authorities want the sulphate level to be reduced to between 1000-1800mg/l this is so sulphate rich effluents don’t damage the sewer infrastructure.

A novel chemical precipitation method has been developed using the addition of aluminium and calcium. The chemical reaction is accelerated using ultrasound and its efficiency is improved.

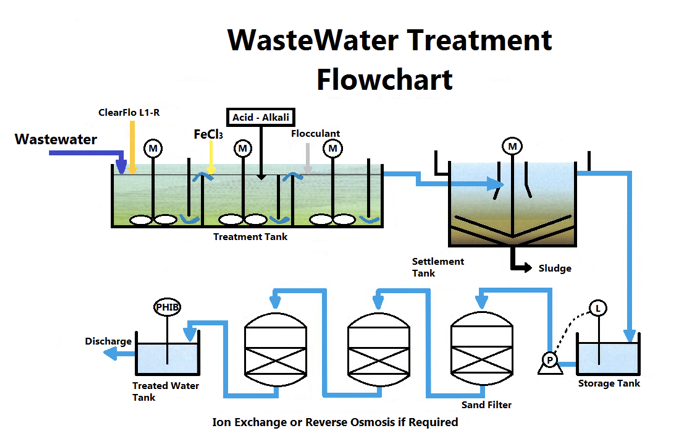

The settlement and precipitation of the solid is aided by the addition of Clearflo L1-R .

Water authorities want the sulphate level to be reduced to between 1000-1800mg/l this is so sulphate rich effluents don’t damage the sewer infrastructure.

A novel chemical precipitation method has been developed using the addition of aluminium and calcium. The chemical reaction is accelerated using ultrasound and its efficiency is improved.

The settlement and precipitation of the solid is aided by the addition of Clearflo L1-R .